Trouble-shooting Surface Mount Technology for Printed Circuit Boards: Parker Hannifin

The Opportunity

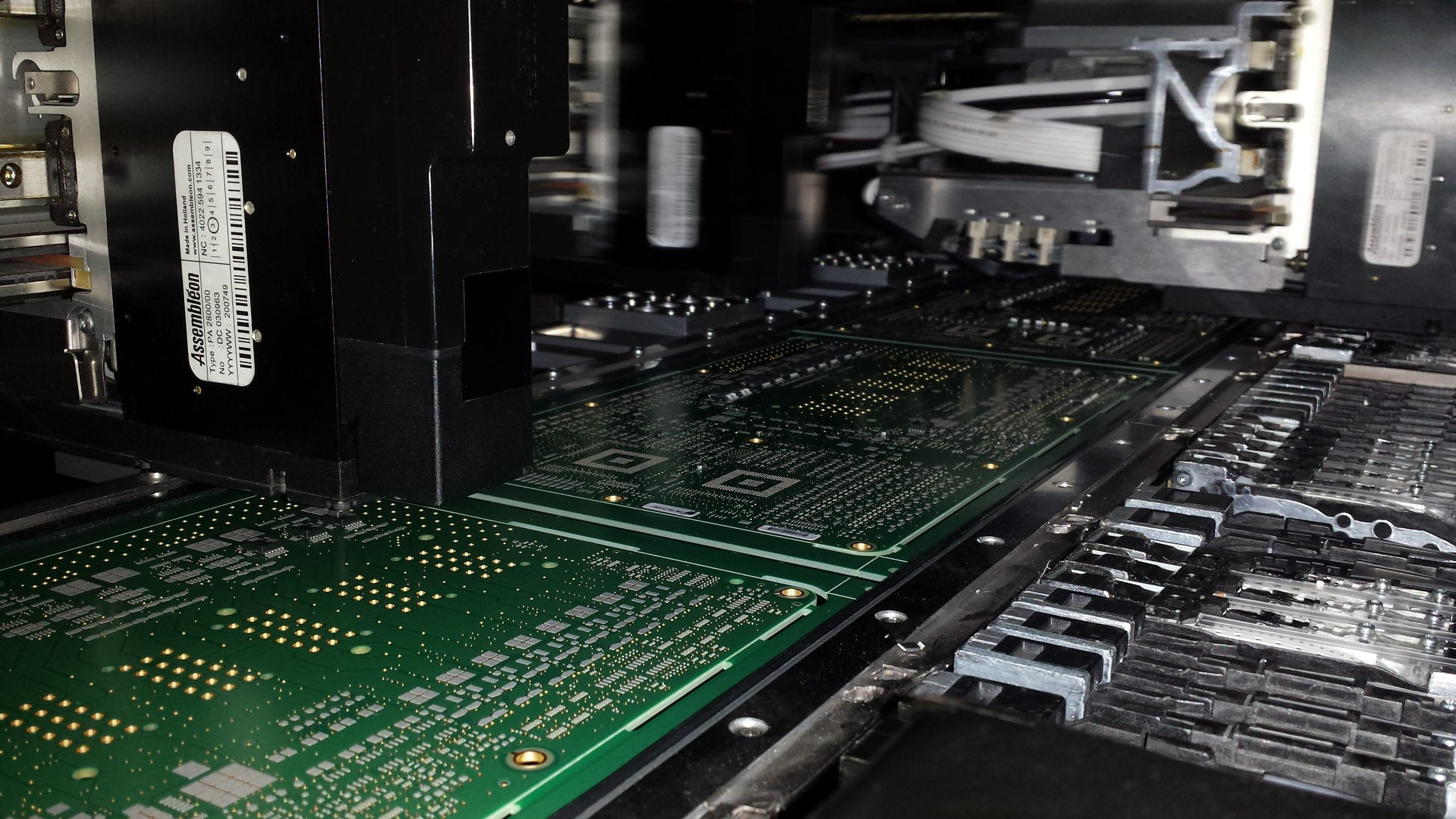

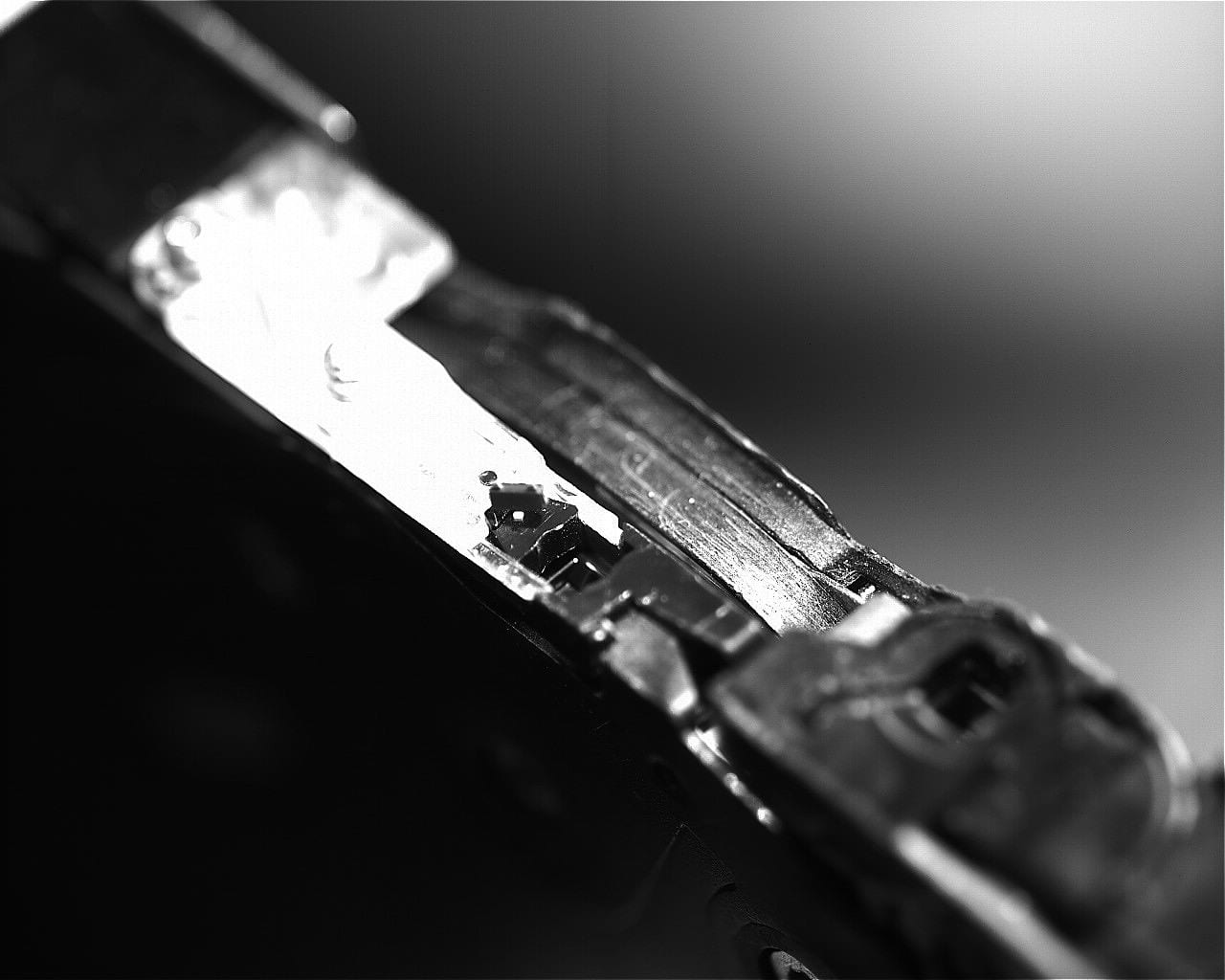

Parker Hannifin uses the surface mount technology (SMT) for circuit board assembly. Hundreds of parts are picked and placed in a matter of seconds. Defects such as missing and wrong orientation of parts were being observed during final quality inspection/testing. These defects mostly occur in chips about 3 x 1 x 1 mm in size and are usually undetected by automatic inspection techniques built into the production process, resulting in lengthy rework or outright scrapping of the parts.

The Approach

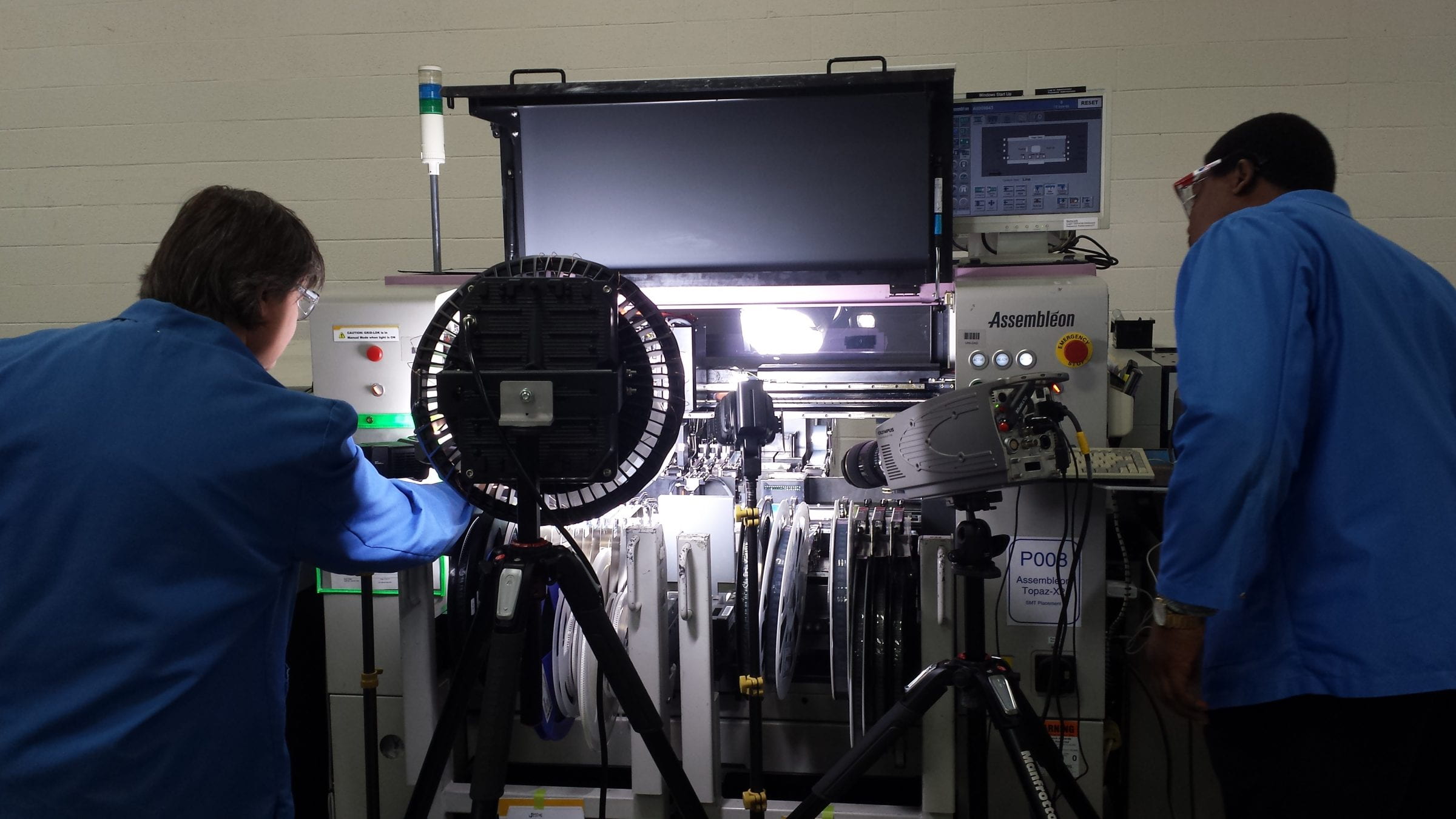

RRC’s expertise in high speed imaging was leveraged by Parker Hannifin to study and determine the root cause of the assembly defects. The “pick and place” processes were studied, using in-production and off-production simulated circuit boards. Large imaging data were analyzed to determine the problem.

The Outcomes

As observed by high-speed imaging, the root cause of the assembly defects is the flipping and “misorientation” of parts in the pockets of unnoticeably faulty twin-tape part feeders. These feeders were isolated for repair/replacement.

The Benefits

- Flexible and responsive access to emerging technology and technical expertise with reduced cost to Parker Hannifin

- Determination of the root-cause of a problem that disrupts / halts production activities

Testimonial

“Collaboration with RRC was instrumental in finding the true root cause of our “pick” issue. Finding and correcting the root cause gave us a significant step improvement in quality and productivity”

— Bob Dann, Technical Services Manager