Building Stronger Bonds in New Sensors: iders

The Opportunity

Developing robust sensors for harsh environments requires innovation and the opportunity to access emerging technology. Iders Incorporated is developing a new device for measuring structural distortions in rail lines. Fabrication of the device requires the use of advanced welding or joining processes to support dissimilar metal bonds.

The Approach

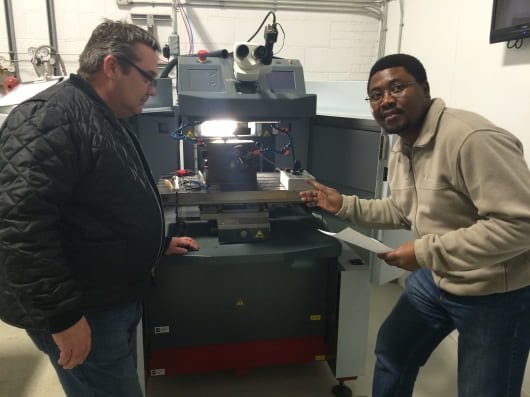

A custom procedure based upon micro-laser welding was developed for fabricating the device. RRC contributed expertise in laser processing of materials and provided direct access to the right laser technology at the CATT Centre.

The Outcomes

A number of unique micro laser joints which meet the required performance characteristics were produced in the sensor assembly. Subsequently, several assemblies were fabricated at the CATT Centre as part of Iders pre-production prototyping and field testing programs

The Benefits

- Flexible and responsive access to emerging technology and technical expertise for the project

- Reduced cost for process development – absolutely no initial capital cost to Iders

- Fabrication of new sensor prototypes without disrupting regular production

Testimonial

“RRC’s expertise and capabilities through the CATT Centre allowed us to overcome a significant materials and fabrication problem associated with an advanced sensor we are trying to bring to market. Our technical problem was solved, quickly and efficiently.”

— David Fletcher, VP and COO, iders

Collaborator: