Thermally Broken Concrete Balconies Project

This project focuses on developing cost-effective systems for the implementation of thermally broken concrete slabs for residential mid/high-rise construction.

This project focuses on developing cost-effective systems for the implementation of thermally broken concrete slabs for residential mid/high-rise construction.

Background

Traditionally, concrete balconies in mid/high-rise residential buildings are designed as an extension to the floor slab, constructed as a one or two-way reinforced concrete slab cantilevered out past the building’s exterior wall.

Without a thermal break, the balcony easily conducts heat, causing a significant amount of heat loss in the winter, leaving the floor slab and window-wall assembly considerably cooler than the interior temperature, and resulting in condensation.

If not properly controlled, materials eventually start to degrade, reducing the integrity and safety of the structure, and even compromising the indoor air quality from mold growth.

Our Research

- This project includes experimentally investigating different forms of thermal insulation materials and different types of rebar and then performing thermal testing and analysis, and structural testing on these materials. BETAC is providing the laboratory space for casting samples and the environmental chambers needed for the thermal testing.

- The main project team includes the College, the University of Manitoba, Crosier Kilgour & Partners and SMT Research.

Status

The first phase of this project started in June, 2016, and is due to complete in August, 2017. The completion of phase two is to be determined.

The objective of this project is to investigate and assess the energy efficiency, effectiveness, and performance of vertical, sloped and horizontal DWHR systems for MURB applications. BETAC will be working with Gary Proskiw, Manitoba Hydro, and Manitoba Housing on this project.

The objective of this project is to investigate and assess the energy efficiency, effectiveness, and performance of vertical, sloped and horizontal DWHR systems for MURB applications. BETAC will be working with Gary Proskiw, Manitoba Hydro, and Manitoba Housing on this project. The majority of information and testing available for DWHR performance was developed for vertical installations. However, the accessible portions of the drain lines in MURBs are predominately horizontal or sloped at 45°.

The majority of information and testing available for DWHR performance was developed for vertical installations. However, the accessible portions of the drain lines in MURBs are predominately horizontal or sloped at 45°.

York Factory First Nation is collaborating with BETAC to perform an air leakage test on a nursing station built in 2000 that has since encountered some roof damage due to ice damming.

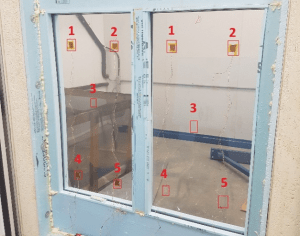

York Factory First Nation is collaborating with BETAC to perform an air leakage test on a nursing station built in 2000 that has since encountered some roof damage due to ice damming. The objective of this project was to compare and evaluate the thermal performance of two samples of a polycarbonate glazing, which behave similarly to Insulated Glass Units (IGU), provided by a local window manufacturer to the Building Envelope Technology Access Centre (BETAC) at Red River College.

The objective of this project was to compare and evaluate the thermal performance of two samples of a polycarbonate glazing, which behave similarly to Insulated Glass Units (IGU), provided by a local window manufacturer to the Building Envelope Technology Access Centre (BETAC) at Red River College.