Research Partnerships & Innovation teaming up with North Forge to host special event that aims to empower Indigenous entrepreneurs

You’re invited – please join us on November 19!

Indigenous entrepreneurs are at the forefront of innovation, blending traditional knowledge with cutting-edge research to build businesses that honor culture and foster community. In today’s world, the strategic use of Intellectual Property (IP) can be a game-changer, driving growth and creating opportunities both locally and internationally.

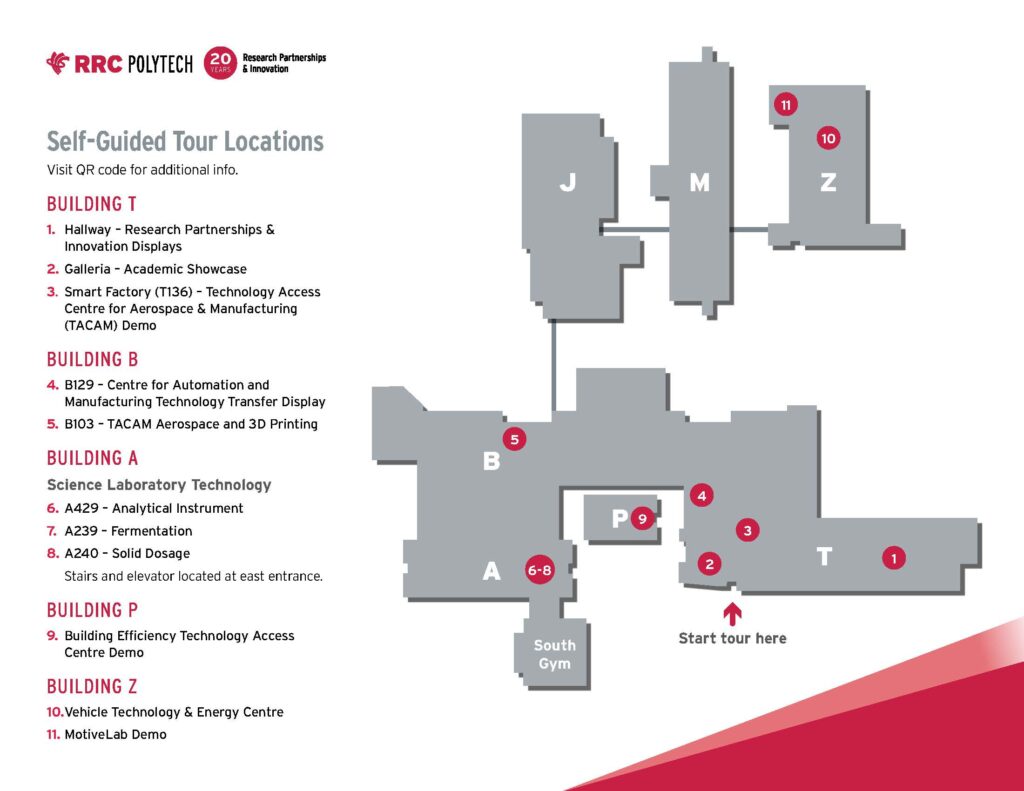

Please join us for a special event at at RRC Polytech’s Exchange District Campus, hosted by Research Partnerships & Innovation (RPI) in collaboration with the North Forge ElevateIP Program, that aims to empower Indigenous entrepreneurs. This gathering will bring together innovators, legal experts, and community partners to explore how IP can be harnessed to protect and scale businesses rooted in applied research and Indigenous knowledge systems.

Date: Tuesday, November 19, 2024

Time: 1:00 – 5:00 PM

Location: Manitou a bi Bii daziigae

Exchange District Campus – RRC Polytech

319 Elgin Ave.

Seating is limited, sign up today

Open to all – Elevate IP is committed to providing inclusive access to IP support for Canadian startups.

North Forge is an ElevateIP Recipient: a national program of Innovation, Science and Economic Development Canada, leading in intellectual property supports for startups in Manitoba and Saskatchewan.