RPI’s 20 Stories for 20 Years – An Introduction by Dr. Jolen Galaugher

To demonstrate the impact that applied research projects make on all Manitobans, we present RPI’s 20 Stories for 20 Years. A compilation showcasing successful partnerships from the past and the present, with a constant focus on the future.

Established in 2004, Research Partnerships & Innovation (RPI) leads the applied research enterprise at RRC Polytech. RPI is a gateway for industry and community to access the vast base of knowledge, capabilities, facilities and networks that reside at Red River College Polytechnic — a Canadian leader in applied research (AR) and commercialization.

RPI also proactively identifies practical AR opportunities that can provide mutual benefit to both the College and potential partners of all sizes with a focus on small- and medium-sized enterprises (SMEs). Through our Office of Applied Research Services (OARS), RPI oversees the administration of all research activities across the College.

Along with granting a variety of credentials and delivering skilled trades programming, AR is one of three pillars that define a polytechnic. It connects all areas of the College, it differentiates us from other post-secondaries in Manitoba, and our unique approach to align Research with Indigenous Strategy and Business Development positions us as a leader on the global stage.

In its two decades of existence, our AR operation has reached an impressive scale through hard work, relationship building and a focused effort to lead innovation in Manitoba. Through our wide array of leading-edge facilities, expertise and technology, we can essentially support any industry, business or community, at any stage. We are eager to strengthen our leadership position in the innovation ecosystem and collaborate on AR projects that drive progress across our province and beyond.

RPI’s areas of specialization include:

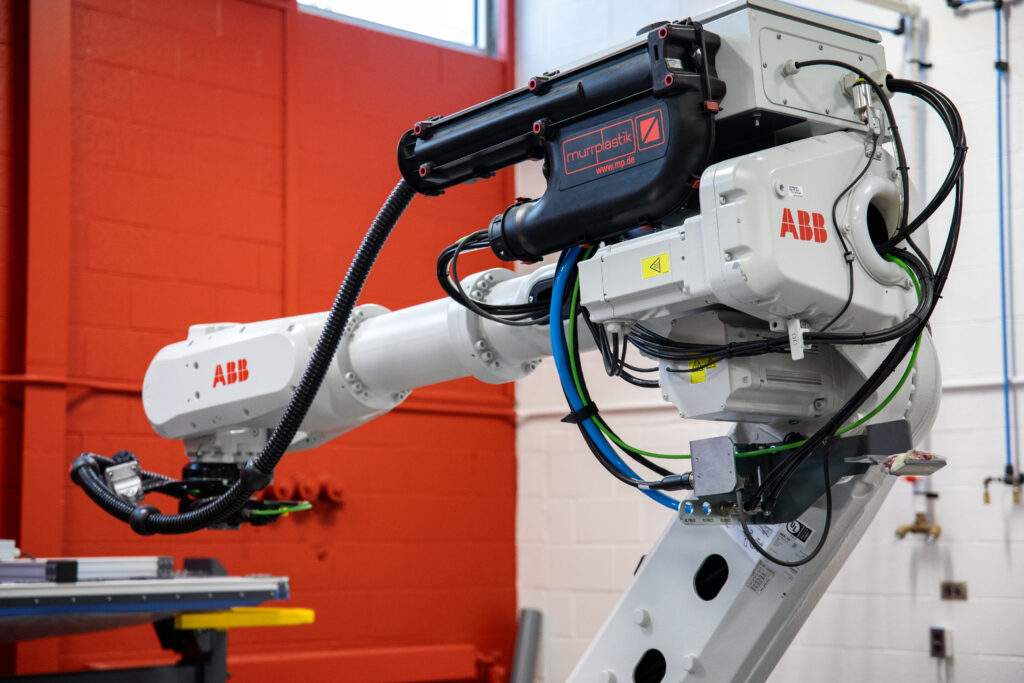

- Advanced Manufacturing and Mechatronics

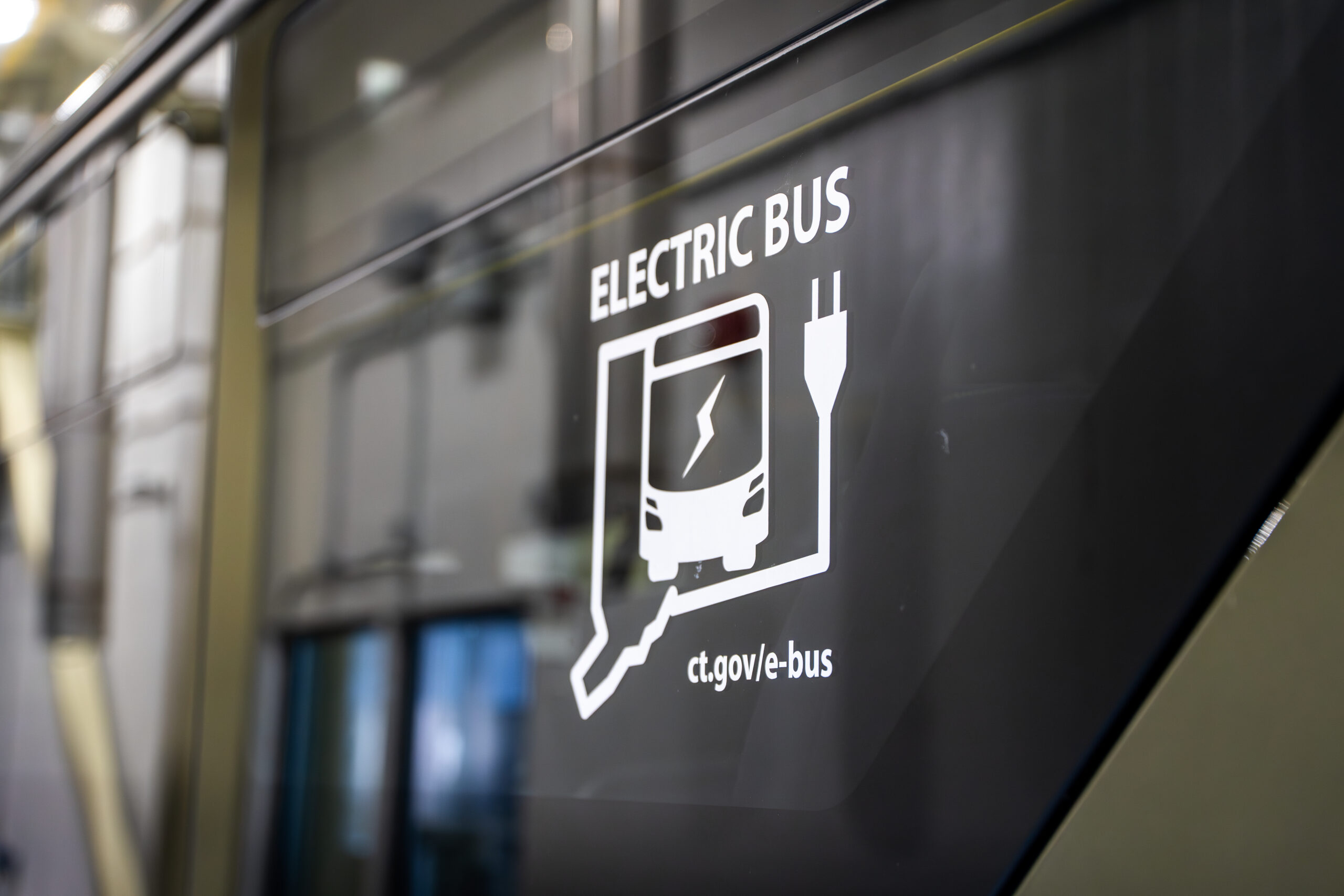

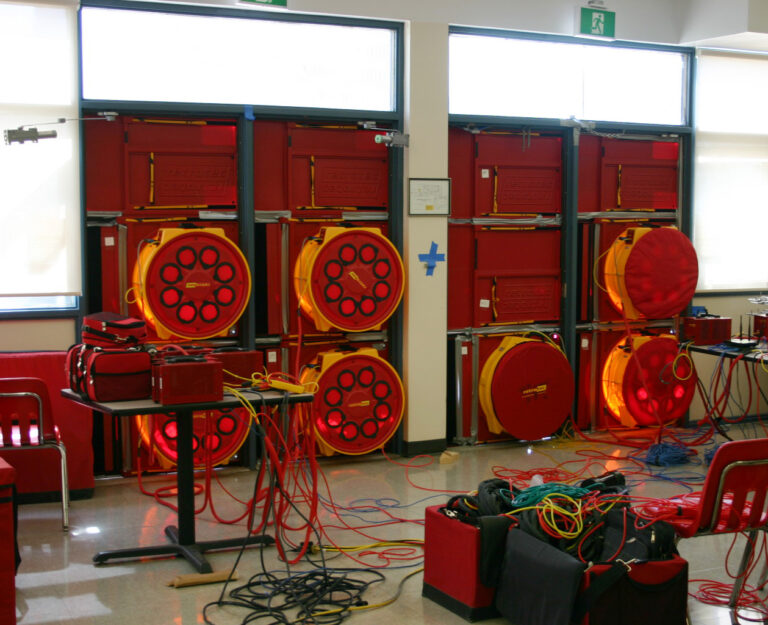

- Cleantech with focus on EV and building efficiency

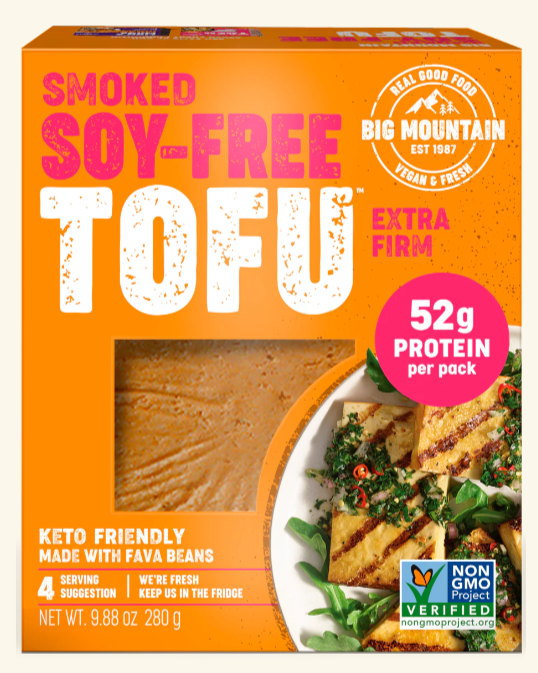

- Health, nutrition and social sciences with focus on culinary research and food innovation

- Early childhood development research

- Enabling adoption of digital technologies including AI and automation

Through collaborative AR projects, we help transform the dreams and ideas of our partners into reality while providing students with invaluable experience through work-integrated learning. Our award-winning work is often admired as the gold standard, and has driven Manitoba forward economically, environmentally, socially and culturally – positioning the province for success in a globally competitive environment.

RRC Polytech has been demonstrating what is possible in Manitoba for 20 years. We want to thank our generous funders and supporters, and of course, all of our partners for trusting us to help achieve their goals by developing new products and processes that drive growth for everyone. We look forward to building on those relationships, as together, we’ll create a prosperous, sustainable and inclusive future for all.

In acknowledgement of our 20th anniversary, we wanted to showcase some of the successes we’ve shared with our partners, past and present. Each week we’ll release a new installment of this online series entitled RPI’s 20 Stories for 20 Years. We’ll provide recaps of previous posts and include updates on related accomplishments achieved since the original publish dates. We’ll also explain what our talented teams learned along the way to make us better at what we do and how the project made a positive impact on RRC Polytech.

With thousands of projects to choose from, we’re confident these stories will highlight our strengths and capabilities, show the depth and breadth of the work we do, and spark interest in pursuing an AR collaboration with us.

Please enjoy these stories and reach out to rpi@rrc.ca so that your innovation can be featured at RPI’s 25th Anniversary!

Dr. Jolen Galaugher

Executive Director, Research Partnerships & Innovation, RRC Polytech