RRC Polytech named a top research College in Canada

Completed applied research projects at the College have increased by one third over the previous year

Red River College Polytechnic (RRC Polytech) has earned the 14th place position in Re$earch Infosource’s annual ranking of the country’s top 50 research colleges.

“RRC Polytech makes innovation possible for our partners in industry and community – and every successful project builds trust in our technology, facilities and expertise,” said Jamie Wilson, Vice President, Indigenous Strategy, Research and Business Development at RRC Polytech.

“Today’s rankings reflect the College’s growing reputation for consistency and productivity that is driven by the work of our Research, Partnerships and Innovation enterprise and at our three Technology Access Centres. They also reinforce that our approach of strengthening relationships with partners and funders across all sectors, driving alignment between stakeholders, and valuing sustainability is accelerating applied research innovation here in Manitoba.”

RRC Polytech completed 170 applied research projects in the 2022 fiscal year – almost 60 more than the previous year – ranking it third in the Medium Tier category and fourth nationwide while posting a total of 117 research partnerships. By maintaining its average of 7.4 million dollars for a second consecutive year, Manitoba’s polytechnic also remains on par with the per-college provincial average of sponsored research income in Alberta and only slightly behind Ontario.

As an added feature to its annual publication, Canada’s Innovation Leaders 2023, Re$earch Infosource also shines a spotlight on college-industry research income as measured by grants, contracts or contributions received from industry sources over the past five years, where RRC Polytech again showed a remarkably consistent annual average of just over 7-million dollars from 2018-2022.

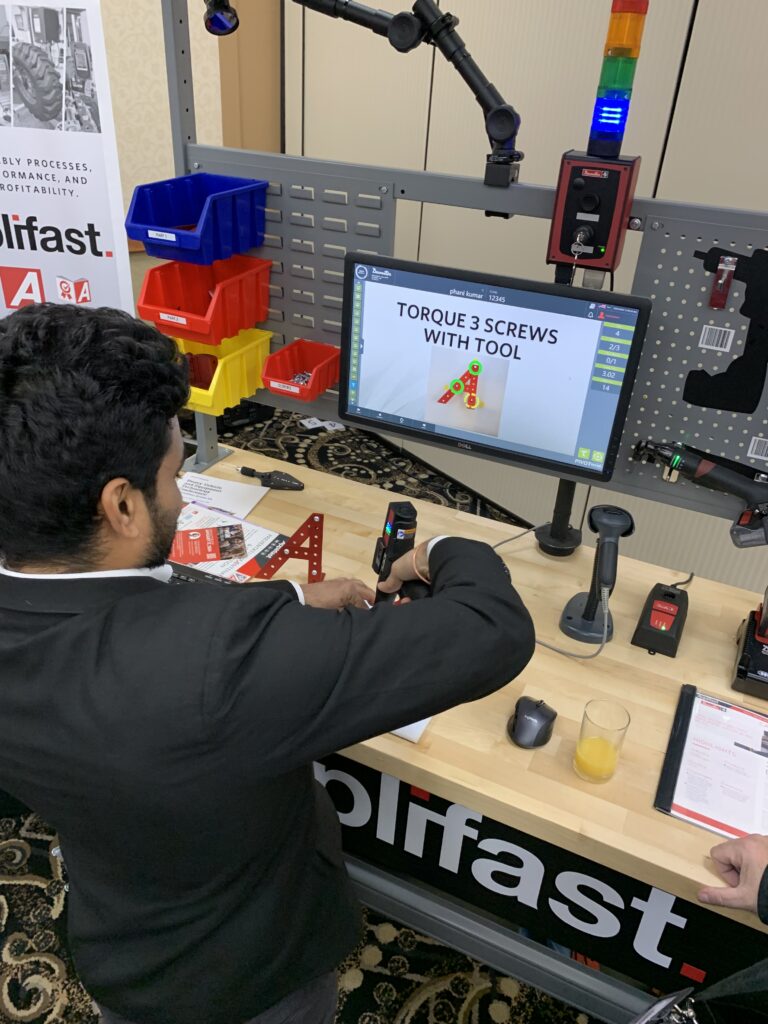

Applied research examples at RRC Polytech include a current partnership between the Technology Access Centre for Aerospace and Manufacturing (TACAM) and StandardAero, who are collaborating to test and validate that cold spray technology could be effectively implemented for repairing aircraft components.

The College’s Vehicle Technology & Energy Centre (VTEC) continues to facilitate the shift to electrification and zero-emission fuel sources with projects aimed at expanding workplace charging capabilities; partnering with Seven Oaks School Division, Noble Northern and the Canadian Shield Foundation to develop a diesel-to-electric conversion kit for school buses; and even building on the success of completed projects by repurposing batteries from Winnipeg Transit electric bus trials in storage systems on fast chargers also created on campus.

The most comprehensive example is From Lab to Table, a Culinary Research Review in the form of a cookbook that shares the delicious outcomes of the applied research conducted at the Prairie Research Kitchen (PRK) since 2014, while documenting the history of Manitoba’s only Technology Access Centre that blends food science and culinary arts. From discovering and developing novel uses for pulse and soybean products to upcycling food industry by-products and even embracing insects for protein, this unique cookbook is available at researchrecipes.ca.

“Celebrating the variety of products, techniques and technology that our researchers, staff and students have worked together with our partners to develop is as important as the volume of projects completed,” said Wilson. “Because regardless of the size or scope of the project, from entrepreneurs in search of support to launch and grow their business idea to established enterprises seeking advancements to propel them into the future, we want everyone to know that in addition to training the workforce of tomorrow, RRC Polytech is also here to provide innovative solutions that elevate all Manitobans.”