Recycled Batteries to Give Electric Vehicles a Boost at Red River College

This week, Canada’s Minister of Natural Resources, the Honourable Amarjeet Sohi, announced a $60,000 investment towards a new electric vehicle (EV) charging station at Red River College’s (RRC) Notre Dame Campus.

“This investment in clean energy technologies will help ensure that Canada remains a global leader in clean energy. The Government of Canada continues to work to reduce pollution, foster change in our transportation choices and leave a cleaner planet for future generations,” said Minister Sohi.

This new Level 3 charging station, which is set to be operational by summer 2020, will use recycled lithium batteries sourced from New Flyer Industries’ fleet of electric buses. Using the recycled batteries will help improve the performance and reduce the cost of operating the station.

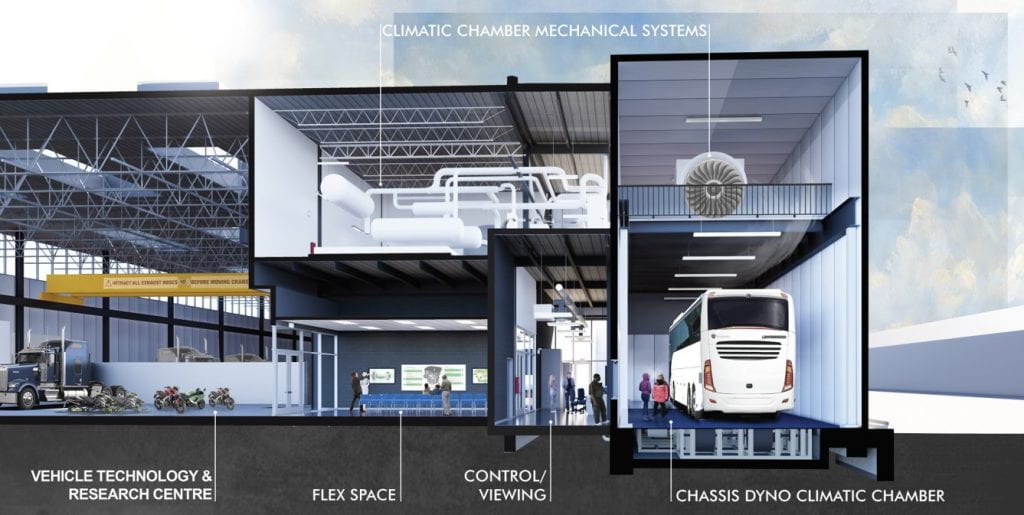

Currently, RRC operates five EV chargers at its Notre Dame Campus – one Level 3 charger, and four Level 2 chargers. The chargers are available for public use and are integral to research projects through the College’s Vehicle Technology & Energy Centre (VTEC).

“This investment will help the College to increase our current clean technology research activity on electric vehicles, along with renewable and alternative energy sources. We’re proud to continue our work in helping to develop sustainable infrastructure and technology that will benefit the environment and economy in Manitoba and across Canada,” said Ray Hoemsen, Executive Director, Research, Partnerships & Innovation at RRC.

RRC was the first organization in Winnipeg to install and operate a Level 3 charger in March, 2015. Level 3 stations can charge an EV up to 80 per cent charge in less than 30 minutes; this is compared to a 220/240V Level 2 charger, which can take four to six hours to get to full charge, or an 110/120V Level 1 charger, which can take up to 12 hours.