RPI’s 20 Stories for 20 Years – Prairie Fava

To demonstrate the impact that applied research projects make on all Manitobans, we present RPI’s 20 Stories for 20 Years. A compilation showcasing successful partnerships from the past and the present, with a constant focus on the future.

Prairie Fava and RRC Polytech’s Prairie Research Kitchen (PRK) are a dynamic applied research duo. So much so that in 2020, PRK won the Canadian Association of Research Administrators’ (CARA) Research Partnership Award for its ongoing work with Prairie Fava.

“PRK, and in particular, Mavis McRae, have assisted us since I brought in one of my first bags of beans for assessment and product development support in 2016,” says Hailey Jeffries, President of Prairie Fava, Canada’s leading grower and ingredient supplier of fava beans.

“PRK has played a role in so many stages of our growth and is an invaluable resource for Canada’s plant-based food industry.”

Hailey Jeffries founded Prairie Fava after searching for alternative protein sources for her mother, who was undergoing cancer treatment. She knew fava flour could enhance fibre and protein content in a wide range of recipes, but the market was limited in 2016, and so was Prairie Fava’s capacity for culinary research and recipe development.

At the time, PRK was still the Culinary Research & Innovation program (CRI). The program’s goal was to help food manufacturers better access the Manitoba food service industry, and Prairie Fava was the perfect candidate.

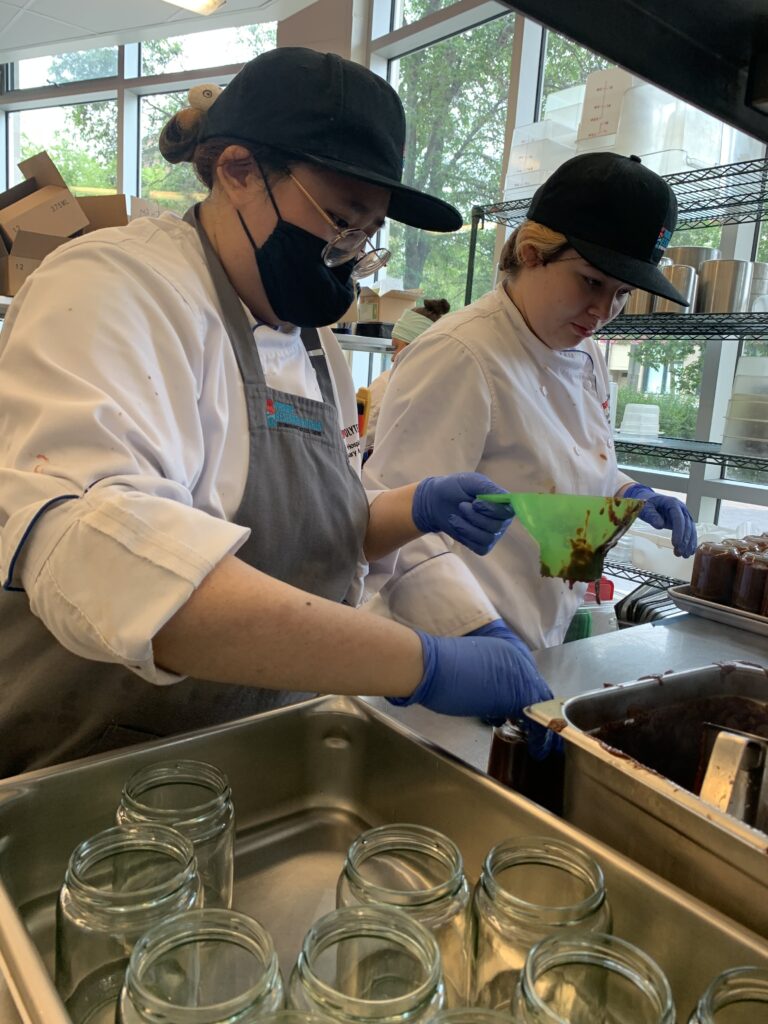

So PRK started developing recipes for Prairie Fava that built on the fava bean’s greatest strengths while addressing the absence of gluten, which is typically essential for dough structure and teaching culinary students food science skills. Together, they’ve done extensive recipe development to prove that fava flour products can enhance the nutritional profile of existing food formulations and be used to develop new products, like plant-based fava bean spread.

“Having input from an applied research team provided me with valuable insights and direction that could only come from a place where culinary and food sciences are combined,” says Jeffries.

Both parties have grown immensely over the course of the partnership. In 2019, the CRI program received a game changing Technology Access Centre (TAC) grant, the Culinary Research Innovation Suite opened and all of the programs and the new facility were pulled together under one name: Prairie Research Kitchen. The same year, Prairie Fava won the Start-Up of the Year Award at the Manitoba Chambers of Commerce Business Awards.

Outside of recipe development and optimization, PRK does plenty of other research to support Prairie Fava. Most notably, in 2022, the PRK pioneered a unique processing method that led to the creation of the first commercialized allergen-free fava tofu.

“Prairie Fava has been a great partner of ours since the beginning. Working with them has showcased our ability to bring a chef’s experience and perspective to applied research,” says Mavis McRae, Director of the Prairie Research Kitchen. “We’re grateful for their support, and thankful to have grown alongside each other over the years.”