Located in Winnipeg’s historic Exchange District, Paterson GlobalFoods Institute (PGI) is home to the Prairie Research Kitchen and to RRC Polytech’s School of Hospitality and Culinary Arts. In this state-of-the-art teaching facility, students acquire skills in professional baking and patisserie, hotel and restaurant management, and professional culinary arts.

Prairie Research Kitchen’s proximity to the School allows for quick and efficient collaboration with instructors and convenient access for student employees.

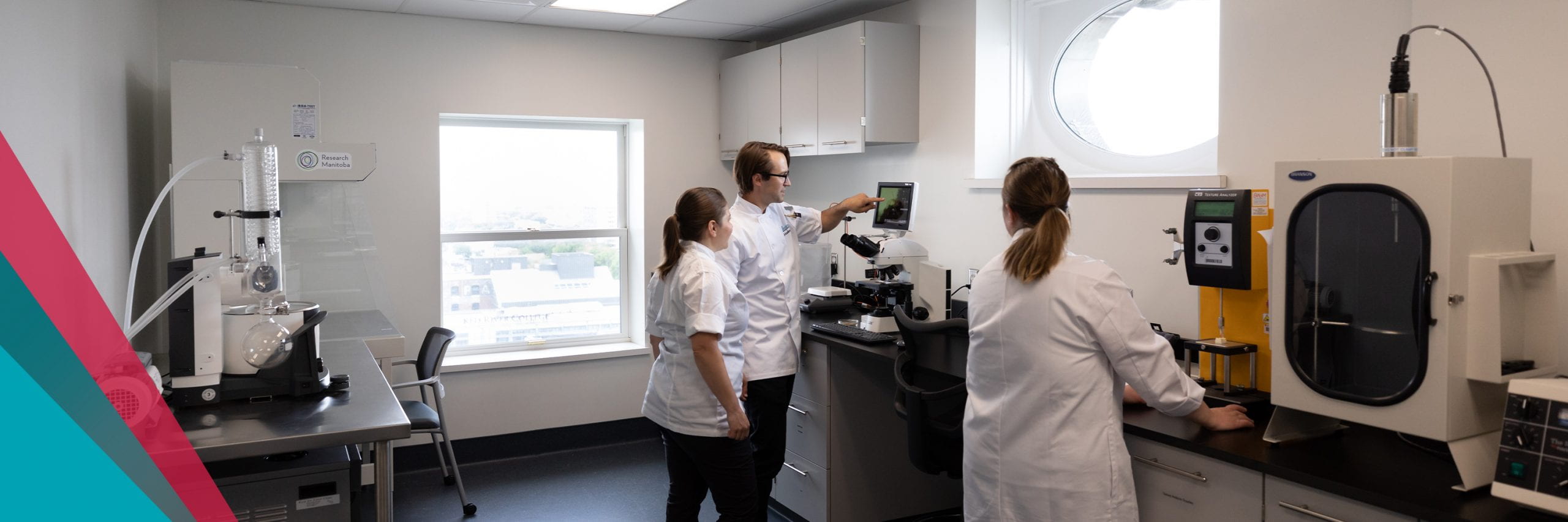

Opened in 2019 and located on the 11th floor of the Paterson GlobalFoods Institute, the Prairie Research Kitchen is a collaborative space for companies that partner with the Prairie Research Kitchen on applied research projects to work side-by-side with RRC Polytech researchers, chefs and students.

With a total floor space of 4600 sq ft including 2300 sq ft of lab space, the Prairie Research Kitchen features modular spaces to accommodate project-specific equipment as needed. The facilities come fully-equipped with everything you need to advance your food product or service to the next stage of the food development process, including:

Prairie Research Kitchen’s demonstration kitchen, with its sit up bar overlooking the kitchen, is ideal to run ideation sessions with clients, researchers and instructors or showcase new products to buyers.

Our food quality lab offers the perfect structure to analyze the quality and safety of new culinary products and ingredients.

The research and development kitchen is great for exploring the potential of new equipment and techniques such as fermentation, culturing, and charcuterie.

Ideal for food photography, our food styling studio is equipped with cameras, backdrops and lights, as well as video and photography editing software.

Note: The facilities of the Prairie Research Kitchen were made possible thanks to funding from the Canadian Foundation for Innovation (CFI) and Research Manitoba.

Through Prairie Research Kitchen, you can access a full-service applied research team. We can partner with other RRC Polytech departments to leverage all resources to better serve local companies, examples of equipment that can be used for our clients’ projects include:

From throughout the College, we can connect you with skills in manufacturing, IT, marketing, graphic design and have partnerships with incubators, investors, business leaders and government.

The Prairie Research Kitchen serves Western Canada’s vibrant food production industries state-of-the-art technology. Leading edge equipment and food preparation techniques are available for clients to be used in partnership with our team of expert chefs, researchers, instructors, and students.

RRC Polytech campuses are located on the lands of the Anishinaabeg, Ininiwak, Anishininwak, Dakota Oyate, and Denésuline, and the National Homeland of the Red River Métis.

We recognize and honour Treaty 3 Territory Shoal Lake 40 First Nation, the source of Winnipeg’s clean drinking water. In addition, we acknowledge Treaty Territories which provide us with access to electricity we use in both our personal and professional lives.